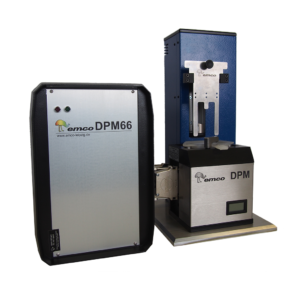

emco DPM 66 Dynamic Penetration Measurement

The dynamic penetration measurement of emco is based on absolute, calibrated ultrasonic transmission measurement. It is used as an innovative method for analysis of the nature of paper and other materials, liquids and the dynamic of their interaction.

Features

- Absolutely calibrated measurement values in decibel

- Fully automatic measurement sequence

- Automatic calibration before each measurement

- Measurements are carried out at intervals of 1 millisecond and cover a high dynamic

- Measurement under dynamic pressure of the liquid up to 3 mbar

- Modular structured supplies und special equipment

- Mobile use of the measurement system (suitcase transport)

- Delivery of the measurement cell with certificate

- Determination of the paper characteristics for processing: absorbancy, capillarity and e-modulus

- Combinable with the dynamic expansion module (emco DDPM)

- Combinable with the heating module

Applications

- Quality assurance

- Research and development

- Optimization of recipes, processes and technologies

- Investigation of troubles and warranty claims

- Evaluation of reference offers and substitution

- Convincing quality proof

emco DPM application cases

- Examination of paper structures by means of water penetration of front and back side

- Detection of surface and internal sizing as well as starch

- Analysis of coated papers and coating base papers with various liquids

- Analysis and detection of the dynamic of the capillarity of paper

- Analysis of the wetting phase with various liquids, with correlations to printability, mottling, blistering, lacquering, penetration from printing colours, moisturisers, InkJet colours etc.

- Examination of decor papers and laminates, dynamics of impregnating resin absorption and simultaneous expansion

- Newsprint: analysis of short-term hydrophobicity, absorption behaviour of printing inks and wetting agents, dynamics of expansion

- Label papers (all preliminary and intermediate stages), analysis of printed labels, verification of embossing, lacquer penetration, detachment behaviour with caustic soda lye up to 90 °C with simultaneous expansion measurement in MD and CD

- Examination of special papers, felts, cigarette papers, filter papers, etc.

- Complaint processing (printing, laminating, stamping, lay-flat, fanning-out effects)

- Carrying out job measurements, interpretation aids

- Simultaneous measurement of ultrasonic transmission and expansion

- Combination of ultrasound transmission and expansion

- Absolute signal calibration (dB) always provides the reference to the statics of the paper (stiffness, E-modulus, fiber bonding, wet fixed bonding) and allows the absolute comparison between papers

Successful application of the measurement method - worldwide.

The following materials, liquids and their interactions have been tested so far:

- Paper

- Cardboard, paperboard

- Wood up to 10 mm

- Textiles

- Leather

- Nonwovens

- Ceramics

- Water and aqueous liquids

- Coating colours

- Printing inks and components

- Varnishes

- Oils

- Toluene, acetone

- n-heptane

- Latex

- Starch

- Impregnating resins

- Adhesives

- Solvents

- Caustic

- Acids etc.

Technical data

Measuring frequency

1 and 2 MHz – standard

Measuring area

each frequency 2x 10 mm Ø

Measuring range

0 till -60 dB

Measuring duration

up to 24 h

Measuring beginning

approx. 8 ms

Test liquid

distilled water

Power supply

100/240 VAC, 50/60 Hz

PC-interface

USB 3.0

Software

emco DPM66 and emco DPM Viewer

Optinonal module

- emco DDPM Dynamic Expansion Module

- Heating module

Spare parts and accessories

emco DPM66 Sample Holder 17

Open sample holder for double-sided measurement of material samples

Art.-Nr. EEP-00011

emco DPM66 Sample Carrier Plate 14.1

Carrier plate made of plexiglas with Teflon foil

Art.-Nr. FTM-00378

emco DPM66 Sample Holder 16

Open sample carrier for measuring material samples with higher thickness on both sides

Art.-Nr. EEP-00012

emco DPM66 Sample Carrier Plate 14.2

Polypropylene carrier plate

Art.-Nr. FTM-00377

emco DPM66 Sample Holder 14.1

Sample holder with carrier plate made of plexiglas with Teflon foil, for one-sided measurement of material samples

Art.-Nr. EEP-00013

emco DPM66 Adhesive Tape Type Scotch 3M - 410

Double-sided adhesive tape, 1000 pcs. punched parts (50 mm x 70 mm)

Art.-Nr. EZH-11303

emco DPM66 Sample Holder 14.2

Sample holder with carrier plate made of polypropylene, for one-sided measurement of material samples

Art.-Nr. EEP-00014

emco DPM66 Cuvette

Measuring cell insert for the use of non-watery test liquids

Art.-Nr. 1130570

Video presentation

Product information

- Delivery time: 1-2 weeks

- Article number: EEP-00051

Downloads / Documents

Contact

Do you have any questions about our products?

Further products

emco DDPM – Dynamic Penetration Measurement

The emco DDPM – expansion module as a integral part of the DPM system solution for

the determination of dynamic of the wet expansion of paper