Dynamic of Absorbancy

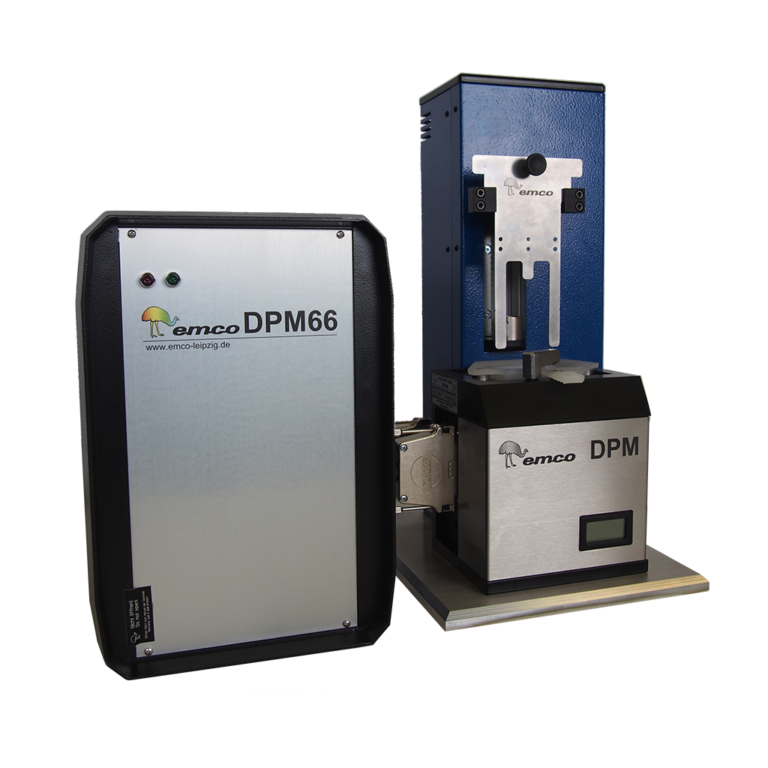

Measuring principle

- Indirect determination by ultrasonic transmission measurement emco DPM via the E-modulus change due to water absorption of the paper fibre wall.

- By sample preparation on a carrier, one-sided or two-sided liquid contact is possible.

- The presence of starch affects the hydrate film formation around the fibres and makes starch relevant to the process both on the surface and in the mass (IMPS 2018, Beltz, Daivapu).

- Measurements possible with fountain solution, solvent, impregnating resin, water glass and other bipolar liquids, normalised aqua dest.

Measurements and results

- emco1 (tStart) to emco7 (tEnd) of page 1 and 2 in the printing process-relevant period (tStart to tEnd)

Important notice:

There is no correlation with the Cobb test as it has no correlation with sizing (IMPS 2018, Beltz, Daivapu).

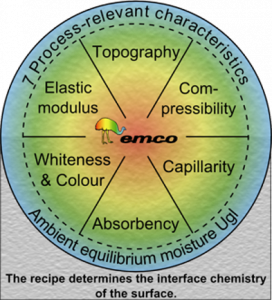

Significance for the printing process

- Dynamics of the additive absorbancy

- Range of printing speed

- Sideness (differences between side 1 and side 2)

- Water resistance of the surface

- Conclusions on capillary penetration or fibre absorption

- Evaluation of printing phenomena: smudging, set-off, ghosting, agglutination

Downloads / Documents

Contact

Do you have any questions about our products?

Further products

emco DDPM – Dynamic Penetration Measurement

The emco DDPM – expansion module as a integral part of the DPM system solution for

the determination of dynamic of the wet expansion of paper

emco DPM

The dynamic penetration measurement of emco used as an innovative method for analysis of the nature of paper and other materials, liquids and the dynamic of their interaction.