emco PMM Paper Management Moisture

The emco PMM – Moisture as a modular part of the emco Paper Management is an equipment system for job-related determination of the equilibrium moisture content in printed media and documentation in a database. In printing technologies such as heatset, wherein the moisture content of paper is extremely lowered in the dryer, the setting of optimum moisture by re-wetting is the technological challenge.

Features

- Determination and documentation of the equilibrium moisture of specimen copies and information of the user on the machine

- Ease of use: measurement starts automatically with laying of the print product

- Database for process control, optimization, documentation and knowledge acquisition

Quantities

- Equilibrium moisture GGF [da% RH] as target, actual and their deviation

- Weight of the print product [g]

- Dewpoint and Cockling temperature [°C] for storage and transport conditions

- Monitoring of the environment (temperature, humidity, air pressure)

Applications

The adjustment of the equilibrium moisture content of printed materials during packaging is in addition to the print quality the key property for the functionality and stability of the printed product in its life cycle. Problematic consequences for a printed product with incorrect moisture, caused by subsequent climate changes, are:

- Immediate aging of the pulp

- Dimensional change due to expansion or shrinkage as formation of waviness, creasing, marks or greasiness, flatness disturbance, growing (expanding), destroying the homogeneity of the print layer with loss of gloss

- Change in modulus of elasticity leads to a change of the optimal web tension

- Ghosting, set-off and smearing of the freshly printed ink

- Local swelling / shrinkage of the surface with topographic change, which changes the color reproduction / the color distance

- Dew point temperature in the package destroyes the product

- Cockling temperature in the packaging leads to a wrinkled surface, also referred to as cockling

The device system emco PMM – Moisture as a modular part of the emco paper management determines the equilibrium moisture content in printing products and provides the verifiable comparison to a target moisture.

Technical data

Measuring range humidity

1 – 100 % rH

Resolution display

0,1 % rH

Accuracy (25 °C ±2 K)

±1,8 % rH in the range of 20 – 80 % rH

Hysteresis

±1 % rH

Range GGF

0.1 – 10 da% rH (calculated)

Resolutions display

0.1 da% rH

Measuring range temperature

-10 °C – 60 °C

Resolution display

0.1 °C

Accuracy (25 °C)

±0.3 K, ±1 K in the range of -20 °C – 60 °C

Dew point temperature

calculated

Cockling temperature

calculated

Resolution display

0.1 °C

Measuring range weight

0 g – 2000 g

Resolution display

0.01 g

Reproducibility

0.01 g

Operating temperature

10 °C – 40 °C

Storage temperature

0 °C – 40 °C

Power supply

220 V

Dimension

800 mm x 600 mm x 1700 mm

Weight

approx. 55 kg

Product information

- Delivery time: 3-4 weeks

- Article number: EEP-00003

Downloads / Documents

Product request

Further products

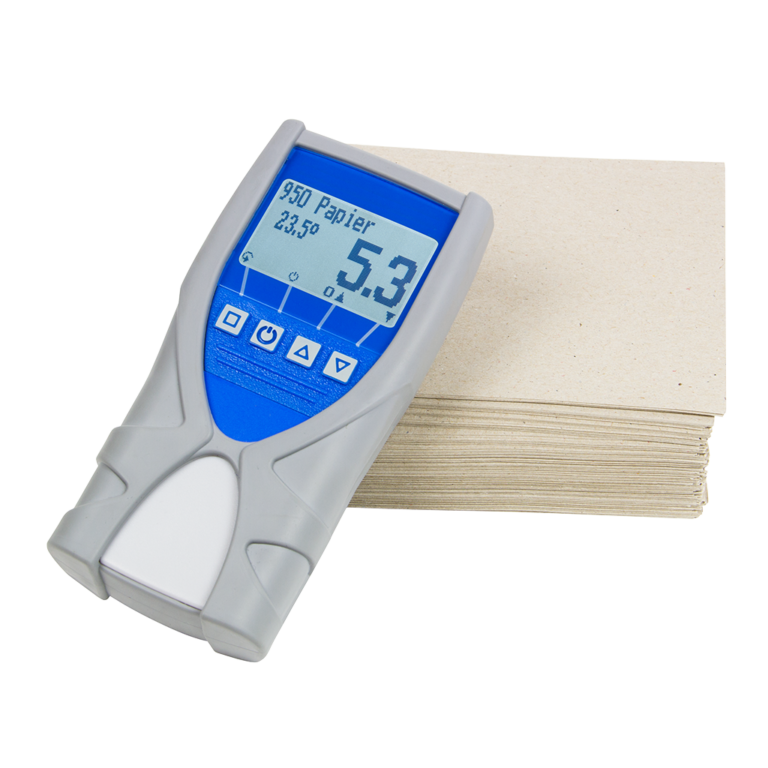

emco RH 2 for paper cores

emco RH 2 Measurement of relative humidity of paper cores The emco RH 2 wih special sensor and adaptor is a robust hand-held measuring instrument

emco MP 5 – Moisture Predictor

The emco MP 5 Moisture Predictor is a universal measuring system for the fast and non-destructive moisture determination of paper, paperboard and pulp on the stationary and running roll through the packaging with a measuring depth of 50 mm.

emco MP P – Moisture Predictor

The emco MP P Moisture Predictor is a universal measuring system for the fast and non-destructive moisture determination of paper, paperboard and pulp in stacks through the packaging with a measuring depth of 20 mm.

emco Dolphin P – Sword sensor for humidity and moisture of paper

Sword sensor for mobile determination of relative humidity, temperature, dew point and moisture in paper stacks and environments

emco RH 5 – sword sensor for humidity, temperature and dew point

Sword sensor for mobile determination of relative humidity, temperature and dew point in paper stacks and environments

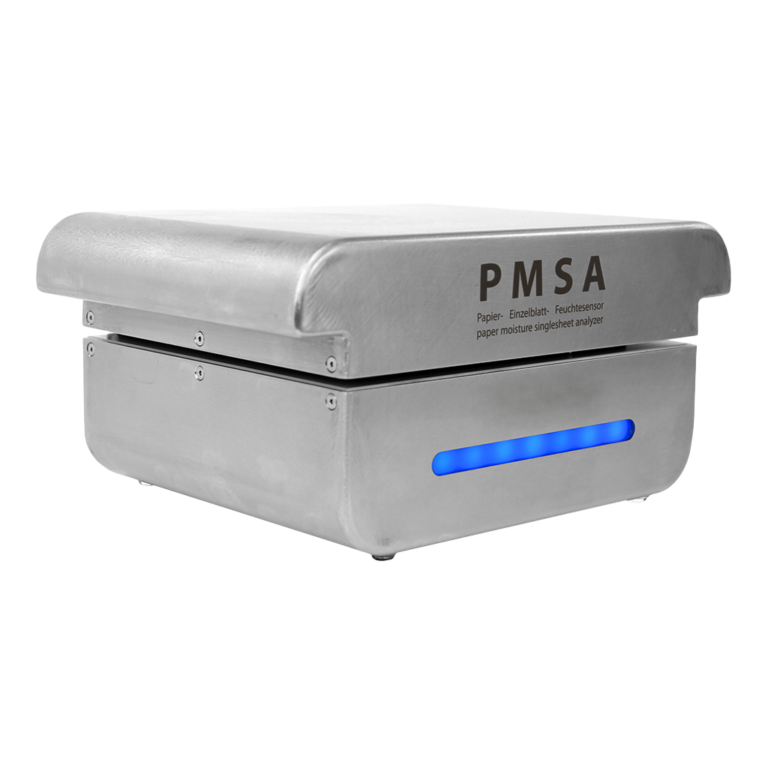

emco PMSA – Single Paper Sheet Moisture Analyzer

Moisture sensor for determination of water content of single paper sheets.