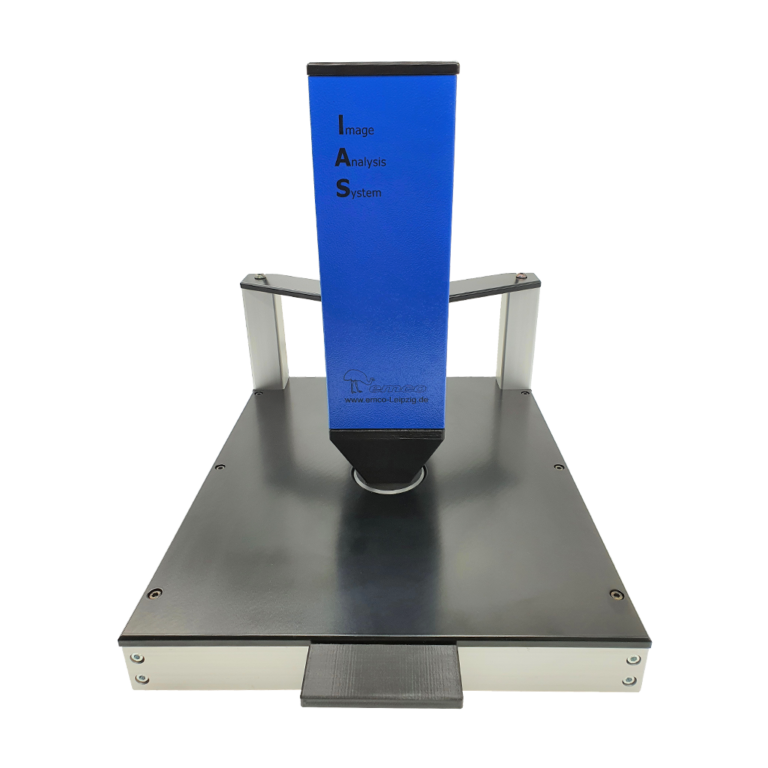

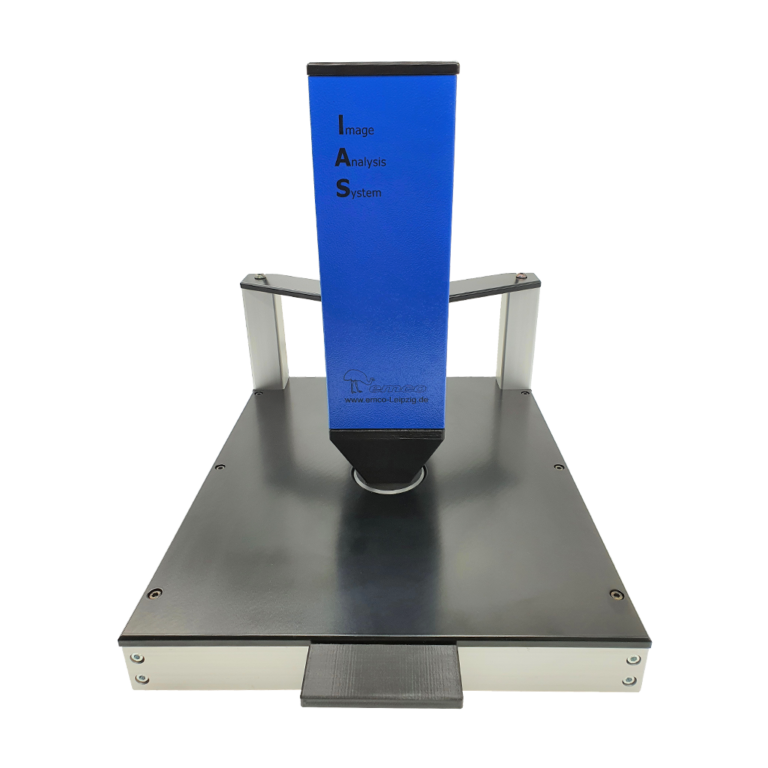

emco IAS Scarredness Tester

The furrows and recesses of papers are called scars.

The scarredness as cause for problems in painting, coating, printing, clogging and laminating has scarcely been investigated and noticed yet as well as its influence on the surface quality.

Scars occur at the production process in the paper machine inter alia as a print of the covers made by wires and felts. Possibly they are shaped decisively by the press of the felts in the press section.

Bigger pores and recesses in the felt result in material accumulation on pressing. Those protrude as pinnacles from the plane of the sheet after the separation from felt and paper surface. By contact with rollers, drying cylinders, calenders etc. under compulsion they are leveled and compacted.

Extreme scars are causes for missing dots and missing dye transfer in the offset.

Scarredness reduces the color transmission. On the decor print the relationship between scarredness and print quality has been proven doubtless.

Features

- Measuring surface 10 mm x 10 mm or 28 mm x 28 mm

- Optional vacuum plate to improve the flatness of the paper

Scarredness quantities

- Scarredness index NI

- Percenting surface

- Average scars size

- Number of scars

- Roughness index RI

Applications

- Investigation of the relationship between scarredness of the coating base paper and mottling of coated paper

- Investigation of the relationship between trapping, printability and print uniformity on the one hand and scarredness on the other hand

- Investigation of the relationship between toner absorption and toner bonding on the one hand and scarredness of photocopying papers on the other hand

- Investigation of the influence of the scarredness for processes such as coating, clogging, laminating and painting

- Quality control

Technical data

Image size

28 mm x 28 mm

10 mm x 10 mm

Application example

decor paper, uncoated board

SC paper, newsprint paper

Dimensions (HxBxT)

480 mm x 360 mm x 440 mm

Weight

11 kg

Scope of supply

device with camera and illumination unit, power supply unit with mains plug, calibration strip, certificate, software, USB-Dongle, PC-ware on request

Available accessories

Product information

- Delivery time: 1-2 weeks

- Article number: 303010-N

Downloads / Documents

Product request

Further products

emco IAS Embossing Tester

emco IAS Embossing Tester The emco IAS Embossing Tester was designed to determine the intensity of embossing in papers.The optical appearance and functionality of papers

emco IAS Cockling Tester

The emco IAS Cocklingtester is used to determine local tensions (bubble content) and global tensions (waviness), which are permanently visible after wetting.

emco IAS Press Marks Tester

The emco IAS Press Marks Tester is the industry standard for detection and control of the embossing of cigarette papers.

emco IAS Mottling Tester

The emco IAS Mottling Tester determines the optical inhomogeneity of printed and unprinted papers on an area of 30 mm x 30 mm. Mottling is the printing unevenness in solid tone areas.

emco IAS Calender Blackening Tester

The emco IAS Calender Blackening Tester is used to characterise the negative optical impression of SC papers caused by the supercalender.

emco IAS Missing Dots Tester

The emco IAS Missing Dots Tester was designed to determine imperfections in halftone prints.