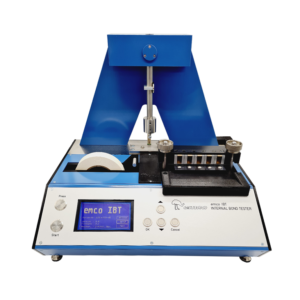

emco IBT Internal Bond Tester

The emco IBT Internal Bond Tester realizes a dynamic measuring principle for determination of the splitting strength of paper, cardboard and compound systems.

By the use of a pendulum machine high shear stresses are simulated which are relevant for evaluation of material behaviour during processes of product finishing and mechanical stress. High processing speed and structual loads stress the fiber strength and interfiber bonding of the paper. Therefore we are talkting about Internal Bond strength test according to Tappi 569 (Scott Bond test). Contrary to the analysis of the mechanical devices of Scott Bond emco IBT is digital and uses the associated advantages.

Fulfilled standards

First European standard ISO 16260:2016 with physical specifications for comparability with the original Scott Bond!

All emco IBT devices meet the specifications since 2003!

Features

- 4 measuring ranges, including Scott Bond low and Scott Bond high

- Sample preparation integrated in the unit (bonding – pressing – cutting)

- Processor-controlled contact pressure and duration

- Menu-guided instrument check (pendulum test and adjustment) and self-calibration

- Monitoring and recording of the test climate

- Sample preparation using emco MSS Multi Sample Slitter or emco PZS Sample Cutting (optional)

- Device function test with the emco Internal Bond Pendulum Check (optional)

Applications

- Quality assurance

- Production control

- Research and Development

- Cigarette paper

Materials

- Printing papers

- Label

- Carton, cardboard, packaging

- multi-ply compound

- Core winder board

- Release paper

- Photo paper

- Decor paper and pre-impregnated paper

- Security paper

- Filter paper

- Nonwoven

- Speciality papers and others

Technical data

Measuring range

4 measuring ranges – 400 J/m², 600 J/m², 1200 J/m², 2400 J/m²

(nominal amount of energy approx. 0.25 J till 1.5 J working capacity)

Option MB 4 to 4000 J/m²

Repeatability

< ±2 %

Angular resolution

0.04°

Sample dimension

25.4 mm x 25.4 mm (1 inch x 1 inch)

Number of samples

5 pieces

Clamping pressure

max. 1410 kPa (at 6 bar compressed air, 0.1 bar step size)

Press time

1 – 60 seconds (1 sec step size)

Power supply

INPUT: 100 V – 240 V AC; 1,1 A

OUTPUT: 24 V DC 1,25 A

Compressed air

6 bar, filtered, oil-free by ISO 8573-1:2001 purity class 6-3-4

Dimension (WxDxH)

500 mm x 400 mm x 520 mm

Weight

approx. 38 kg

Extensions and accessories

Measuring range extension MB 4

Accessory set for internal bond strengths up to 4000 J/m² with smaller measuring area (15 x 25.4 mm²)

Art.-no. EEP-00027

emco Internal Bond Pendulum Check

The emco Internal Bond Pendulum Check enables the functionality of all Internal Bond Testers to be checked on the basis of standardized test specimens in accordance with Tappi 569 and ISO 16260

Art.-no. EEP-00008

Wear and spare parts

Angle set standard

Precision angles for fixing the material sample

(set = 5 pieces)

Art.-no. 841.61001

Anvils

Special sample holder for fixing the material sample

(set = 5 pieces)

Art.-no. 841.61002

Brace

Brace for fastening the precision angles

Art.-no. FTM-00037

Collecting pan

Device for catching the precision angles

Art.-no. FTM-00076

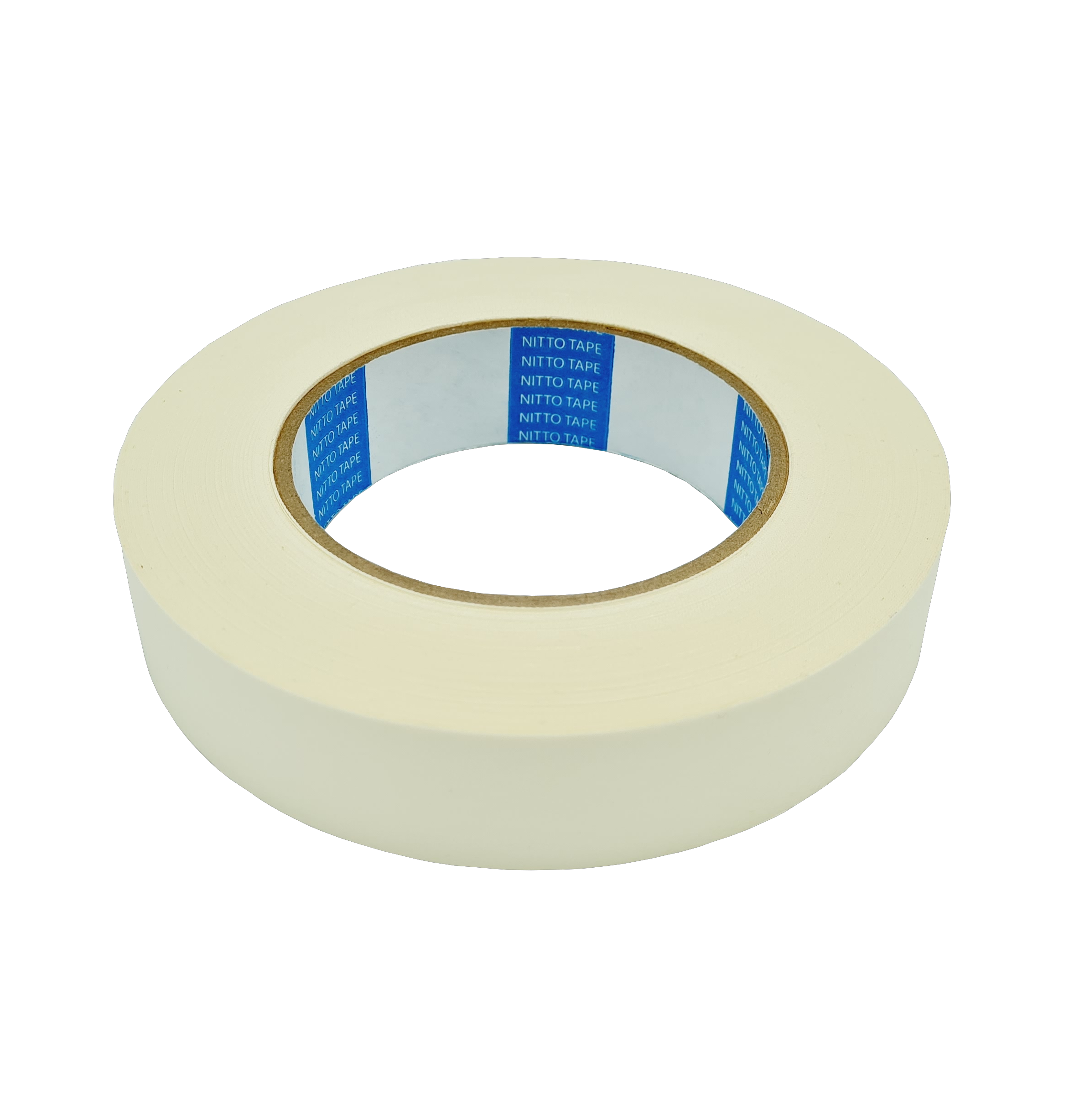

Adhesive tape type 3M TM-410

Double-sided adhesive tape type Scotch 3MTM - 410 with easily removable paper backing

25,4 ±0,2 mm x 33 m

Art.-no. 891.61001

Adhesive tape type Permacel P-50

Double-sided fabric tape type Nitto P-50 with paper backing

25,4 ±0,2 mm x 23 m

Art.-no. EZH000052

Adhesive tape type Tesafix 4961

Double-sided adhesive tape type Tesafix 4961 with paper backing

25,4 ±0,2 mm x 50 m

Art.-no. KTM-00686

Clamp brackets

Springs for clamping the precision angles

(set = 5 pieces)

Art.-no. FTM-00576

Video presentation

Product information

- Delivery time: 1-2 weeks

- Article number: EEP-00058

Downloads / Documents

Product request

Further products

emco PPA – Paper Testing Automat

Configurable, compact testing automates for fully automatic proof of cross-sections of paper, paper board and carton for the use in testing laboratories and on the machine

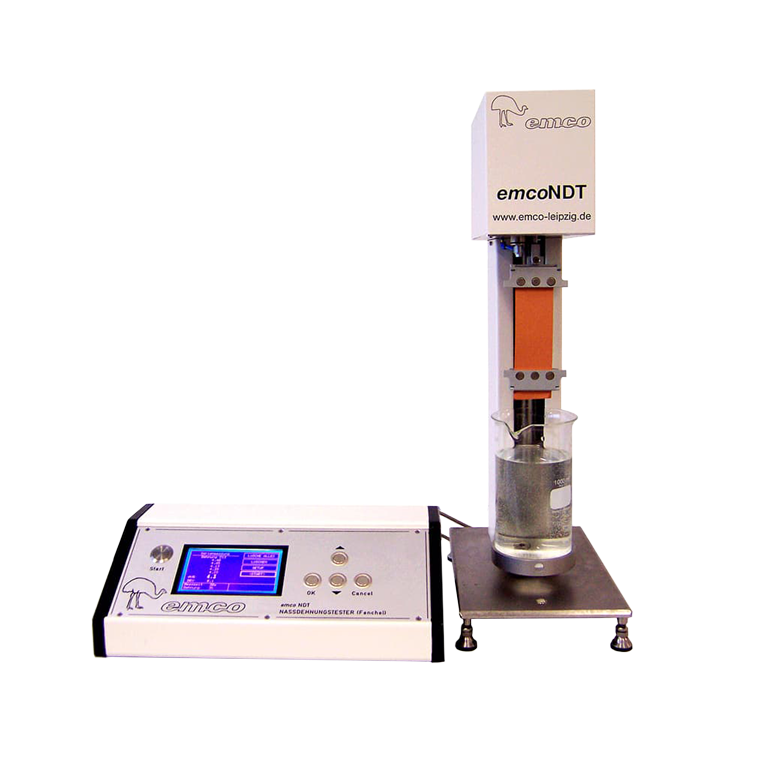

emco NDT Wet Expansion Tester

For determining the wet expansion of paper and paperboard according to Fenchel, Mütek MD und Mütek CD

emco Internal Bond Pendulum Check

The emco Internal Bond Pendulum Check is used to test Internal Bond test devices.

emco GPR Precision Smoothness Tester according to Bekk

Testing instrument for paper, paperboard or film to determine the smoothness of Bekk according to DIN 53107 and Zellcheming V/23/73

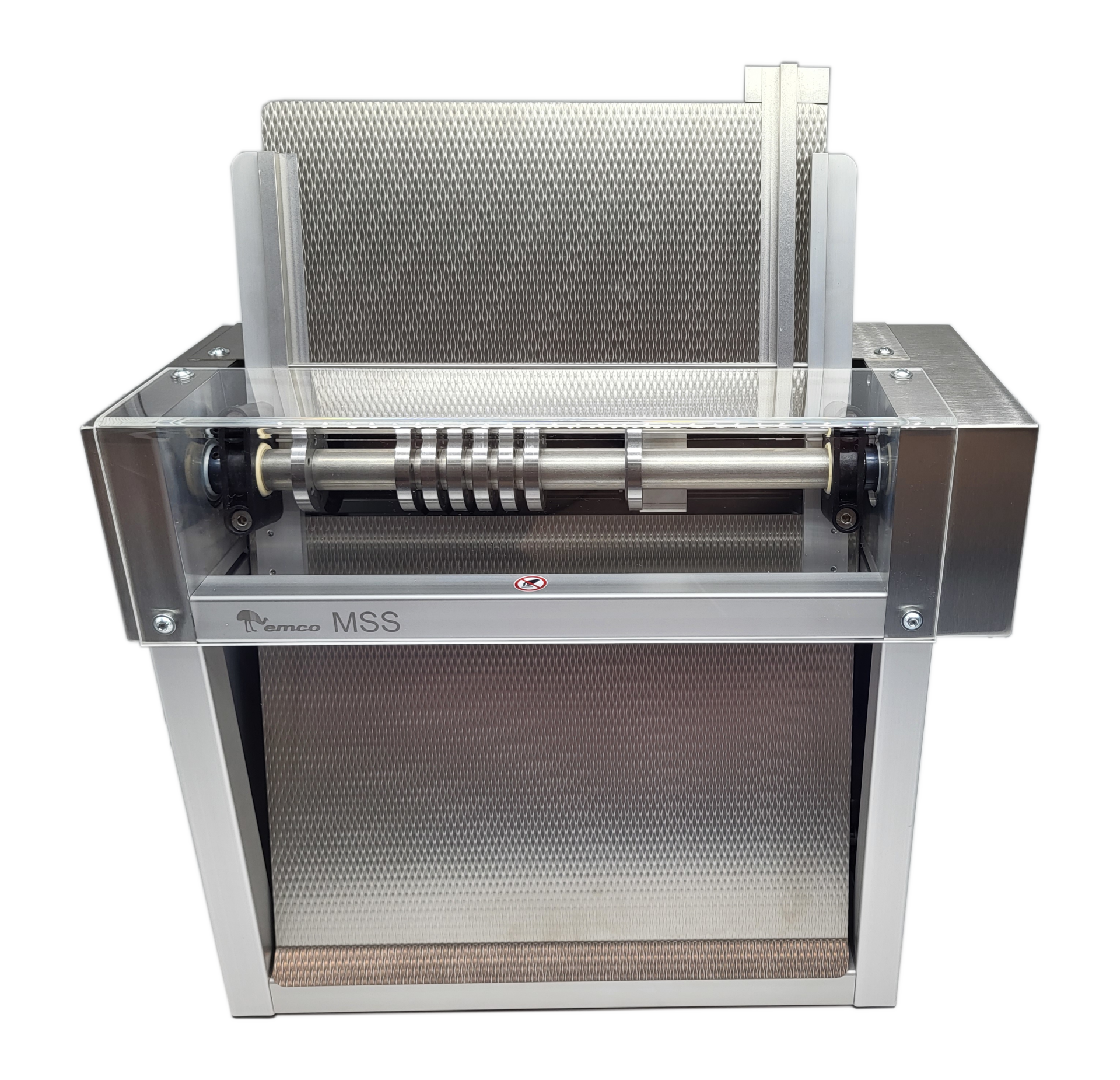

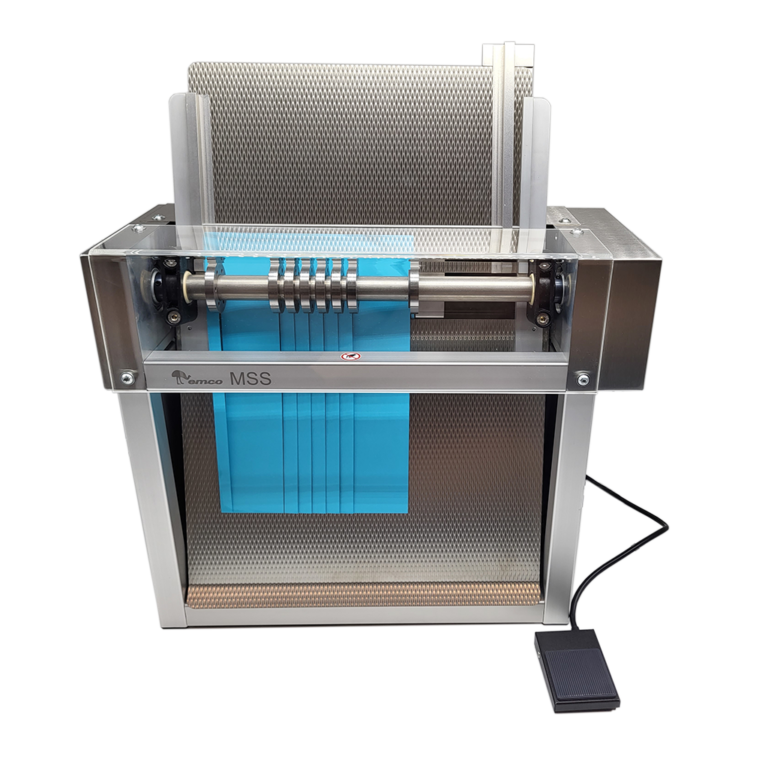

emco MSS Multi Sample Slitter

Electric sample slitter for simultaneous cutting up to 7 stripes with fixed width out of one paper.

emco PZS Sample Cutting

Lever cutting machine with mounted measuring caliper for fast production of test strips for standard-compliant paper testing

emco PTM 5 – Thickness measuring device

Battery-powered, electronic mobile measuring device for the determination of the thickness of non-metal materials, such as papers, textiles, veneers, wood, leather, rubber, plastic and glass