FAQ - emco NDT - Wet Expansion Tester

General information

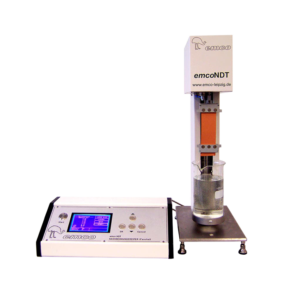

The emco NDT Wet Expansion Tester determines the percentage expansion of a sample in a liquid over time.

The hydrophilic behaviour of hygroscopic materials is tested with water-based liquids. Determined by the prepared clamping direction, the wet expansion in machine or running direction of the sample is obtained due to the fibre swelling.

- Test climate before beginning the measurement (pre-stretching, shrinkage)

- Sample cutting

- Width = measurement is made at a constant weight per mm sample width

- Fibre orientation = the expansion in machine and longitudinal direction differ considerably for most samples

- Sample cross section thickness

- Level of the beaker

- Measurement environment (vibration-free location)

- Measuring instructions (Fenchel, Mütek CD, MD)

- Measuring time

- Strip width 15 mm or 50 mm, special designs are possible on request

- emco NDT Fenchel

- emco NDT with automatic measuring range switching for all three test specifications: Fenchel, Mütek MD and Mütek CD

Standard

The wet expansion according to Fenchel is a measuring instruction which is oriented to a device design. A load of 1 g per 1 mm sample width is defined. A paper strip of 100 mm length and 15 mm width is inserted between two clamps. The lower clamp is rigid and the movable weight of the upper clamp is balanced by a counterweight and connected to a display. The strip expands when immersed in water. This extension is displayed as a percentage.

In the test specification for decor papers introduced by Mütek, the sample is loaded during the measurement with a defined force of 1 N in CD (transverse to the paper web) or 4 N in MD (longitudinal to the paper web) related to a sample width of 60 mm.

- No, DIN 54517:2006-02 describes another method for determining wet expansion in a water bath without tensile loading.

- At present, there are no known studies on the comparability of the measurement results. Individual customers have determined conversion factors.

No, ISO 8226-1:1994 describes a method for determining the expansion of a sample when the relative humidity of the air changes without direct liquid contact.

- No, DIN 53 130 describes a method for determining the expansion of a sample when the relative humidity of the air changes without direct contact with the liquid.

- The measuring principle is borrowed from DIN 53 130.

With the emco NDT the 3 established standards Fenchel (1 g load per 1 mm sample width), Mütek CD (1 N load per 60 mm sample width) and Mütek MD (4 N load per 60 mm sample width) can be determined.

Sample preparation

- Test laboratory with standard climate

- Vibration-free table

- Power connection

- Compressed air

- Data link for result transmission

Yes, compressed air (min. 5 bar, filtered, oil-free and dried) is required to operate the unit. A 1.5 m compressed air hose is included in the scope of delivery.

The strip width depends on the installed magnetic clamp. Therefore the test strip has to be cut externally to 15 mm or 50 mm width and about 160 mm to 180 mm length.

You can choose between Fenchel, Mütek CD and Mütek MD. When a test standard is selected, the load weights are set automatically.

The test standards differ in the load on the sample per mm sample width.

Material production causes deviations across the specimen width for expansion in machine direction and above all in transverse direction. An average value is therefore only possible for directly adjacent test strips.

The sample is inserted into the magnetic clamps after conditioning and cutting. First insert the sample into the upper magnetic clamp and then, after slight tightening, into the lower clamp.

Too tight or too loose clamping is automatically compensated at the beginning of the measurement after unlocking the upper clamp and taken into account during evaluation.

After the measurement, the sample is removed by opening the magnetic clamps. The water must be cleared from the magnetic clamps. For this purpose, absorbent paper or compressed air can be used.

Measurement result

The expansion curve and the current expansion value after the measurement time are displayed. The measurement time thus has a decisive influence and should be set up to at least the maximum expansion.

Single or series measurements can be carried out. The mean value and the standard deviation are displayed for a series measurement. A maximum of 5 measurements are combined to form a measurement series.

Yes, the emco NDT Wet Expansion Tester includes software that allows easy data transfer. The measurement curve and measurement result can be transferred after the set measurement time.

Measured values of different measuring ranges cannot be compared. To avoid errors, a new measurement series is created.

- The sample is torn during the measurement. The sample load was too high for the measurement.

- The sample slips out of the magnetic clamp. The functionality must always be checked before the measurement during preparation.

Factors influencing the measurement result

Yes, the length of the test strip has an influence on the measurement result. The length is defined by the distance between the magnetic clamps at 100 mm. During preparation, no mistakes can be made when the samples are slightly tightened. Small differences in clamping are recorded before the measuring process and included in the measurement result.

The remaining strip underneath the lower clamp should be kept short and can be torn off or cut off if necessary so that the water consumption is not unnecessarily increased.

Yes, the width of the test strip has an influence on the measurement result. The magnetic clamps are optimised for this width. Clamping the test strip is more difficult at higher widths.

The width is of particular importance with regard to the load. A load of 1 g (Fenchel) is applied to each millimetre of sample strip.

Yes, the filling level has an influence on the measurement result. The correct level is marked on the beaker and should always be observed.

A too high filling level leads to buoyancy at the upper clamp and thus to increased load. A too low filling level does not ensure complete wetting of the sample.

Yes, the clamping has an influence on the measurement result. If you clamp the sample too tightly, it is already pre-stretched. If the sample is clamped too loosely, it may not be stretched.

The calculation algorithm with the actual length can only compensate for small clamping deviations.

The measuring time is decisive for the output expansion value.

If the elongation has not yet been completed, this is indicated by the course of the displayed curve. The measurement must be repeated with a longer measuring time.

It is possible to separate the total measuring time into immersion time and drying time. The immersion time and the expansion time are set after leaving the liquid container.

Expendable items

The test liquid must be refilled when consumed. Liquid is continuously lost due to the suction process. There is a mark on the beaker which must be observed.

Inspection and calibration

We recommend that the device be inspected once a year by an emco service technician.

The menu-guided inspection can be carried out by the operator, for example, once a week.

Please use the supplied calibration standards to check the instrument yourself. The exact instructions for this can be found in the operating manual.

Repair and service

- E-mail: emco@emco-leipzig.de

- Phone: + 49 341 27146-0

Special attention must be paid to the effectiveness of the magnetic clamps. If the sample slips out of the holder, replace the magnets.

- Transport packaging (It is recommended to keep the special packaging used at the time of delivery and to use it in case of shipment.)

- Secure weights and compensator carefully: Follow the illustrated instructions.

- The calibration standards are necessary for a check.

- Transport with pallet

- The device must be installed on a flat, stable surface free of vibrations.

- Align the unit to ensure error-free operation.

- Before switching on, make sure that all transport locks have been removed.

- Store the device in climatic conditions that do not damage electronics or mechanics (free of corrosion and electrostatics).

- Check alignment and calibration.

Comparability

The measuring principle of the emco NDT Wet Expansion Tester is based on the structure of the Fenchel tester. The load characteristics defined by the Mütek standard are maintained, but the test setup is different. Due to the special features of the measuring device (penetration from one side, surface tension, buoyancy, cumbersome preparation with sources of error), significantly different dynamics can be detected during comparative measurements. Whether the measurement results can be compared in a specific case must be clarified.